Modern manufacturing facilities rely on complex machinery to maintain production schedules and meet demand. While automated systems and robotics handle much of the heavy lifting, the human element remains critical to operational success.

Industrial technicians serve as the guardians of this machinery, ensuring that every component functions as intended. Their role goes far beyond simple repairs; it involves proactive maintenance, intricate troubleshooting, and a deep understanding of mechanical and electrical systems.

The Core of Preventive Maintenance

The most effective way to keep a factory running is to prevent breakdowns before they happen. Industrial technicians spend a significant portion of their time on preventive maintenance tasks. This proactive approach saves companies time and money by reducing unexpected downtime.

Technicians follow strict schedules to inspect equipment. They check for wear and tear on belts, lubricate moving parts, and test electrical connections. By identifying minor issues early, such as a fraying wire or a vibrating motor, they can address the problem during scheduled downtime rather than amidst a busy production run. This constant vigilance ensures that small anomalies do not snowball into catastrophic failures that halt the entire assembly line.

Troubleshooting Complex Systems

When machinery does fail, the pressure is on to fix it immediately. Industrial technicians must possess strong analytical skills to diagnose issues accurately. They use a variety of diagnostic tools, including multimeters, thermal imaging cameras, and vibration analyzers, to pinpoint the root cause of a failure.

Troubleshooting is often a process of elimination. A technician might start by checking the power supply, then move to the control logic, and finally inspect the mechanical components.

This systematic approach allows them to isolate the faulty part quickly. Once identified, they must decide whether to repair the component or replace it entirely. This decision-making process requires a balance of technical knowledge and practical judgment to minimize the impact on production targets.

Mechanical and Electrical Expertise

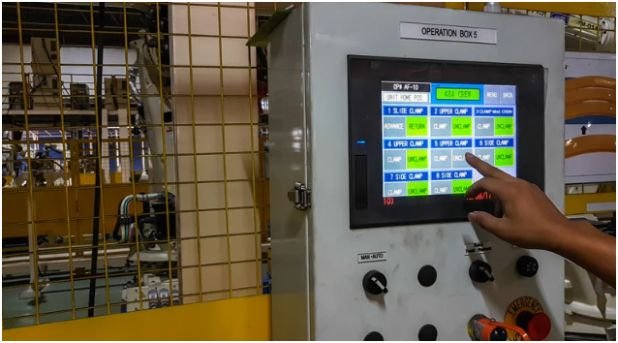

Industrial technicians bridge the gap between mechanical and electrical engineering. They must understand how gears, hydraulics, and pneumatics interact with sensors, PLCs (Programmable Logic Controllers), and motors.

On the mechanical side, technicians deal with alignment, tension, and torque. They ensure that conveyors move smoothly and that robotic arms have the precise range of motion required for assembly tasks.

Electrical responsibilities involve wiring, circuit testing, and programming. A technician might need to recalibrate a sensor one minute and replace a hydraulic seal the next. This versatility makes them indispensable in a factory setting where systems are increasingly integrated.

Ensuring Safety and Compliance

Safety is paramount in any industrial environment. Technicians play a vital role in maintaining a safe workplace by ensuring that all equipment meets safety standards. They regularly test emergency stop buttons, light curtains, and safety interlocks to confirm they are functioning correctly.

Beyond equipment safety, technicians also adhere to strict lockout/tagout procedures during maintenance. This ensures that machines cannot be energized accidentally while someone is working on them.

Their diligence protects not only the machinery but also the operators who work alongside it. By keeping equipment in top condition, technicians reduce the risk of accidents caused by malfunctions or erratic machine behavior.

Managing Heavy Machinery Repair

Some repairs require specialized attention due to the size and complexity of the components involved. Heavy machinery often relies on massive gear systems to transmit power and torque. Over time, these components experience significant stress and wear.

When a major drive component fails, the solution isn’t always a simple swap. It often involves a detailed refurbishment process to restore the unit to its original specifications. For instance, a technician might oversee a falk gearbox rebuild to extend the life of critical drive equipment without the cost of a full replacement.

This type of heavy maintenance requires precision and patience, as even a minor misalignment in a large gear system can lead to rapid failure and extensive damage.

Adaptation to New Technologies

Factories are constantly evolving with the introduction of Industry 4.0 technologies. Industrial technicians are at the forefront of this transition. They install and maintain smart sensors that collect data on machine performance. This data allows for predictive maintenance, where algorithms analyze trends to forecast when a part will fail.

Technicians must stay updated on these advancements. They learn to interpret data dashboards and use software tools to monitor equipment health remotely. This shift from reactive to data-driven maintenance enhances their ability to keep factories running smoothly. It transforms their role from strictly manual labor to a position that requires significant technical and digital literacy.

Conclusion

Industrial technicians are the unsung heroes of the manufacturing world. Their expertise keeps the wheels turning, literally and figuratively. Through preventive maintenance, skilled troubleshooting, and a commitment to safety, they ensure that production lines remain active and efficient.

Their ability to adapt to new technologies and manage complex mechanical repairs secures the longevity of industrial operations. Without their dedication and skill, the seamless flow of modern manufacturing would grind to a halt.